Portable Power Solutions Manufacturer with OEM/ODM Services

ABOUT WITROY

Shenzhen Witroy PV Technology Co., Ltd. is a global ODM/OEM enterprise specializing in new energy solutions, high-end consumer power systems, and industrial control manufacturing. With a strong focus on end-to-end customized supply chain systems, we deliver both tailored and standardized product lines to meet a wide range of industry demands.

Our team combines over 15 years of experience, including backgrounds in Fortune 500 companies and leading global brands. We offer full product lifecycle support—from design and engineering to supply chain execution and precision manufacturing.

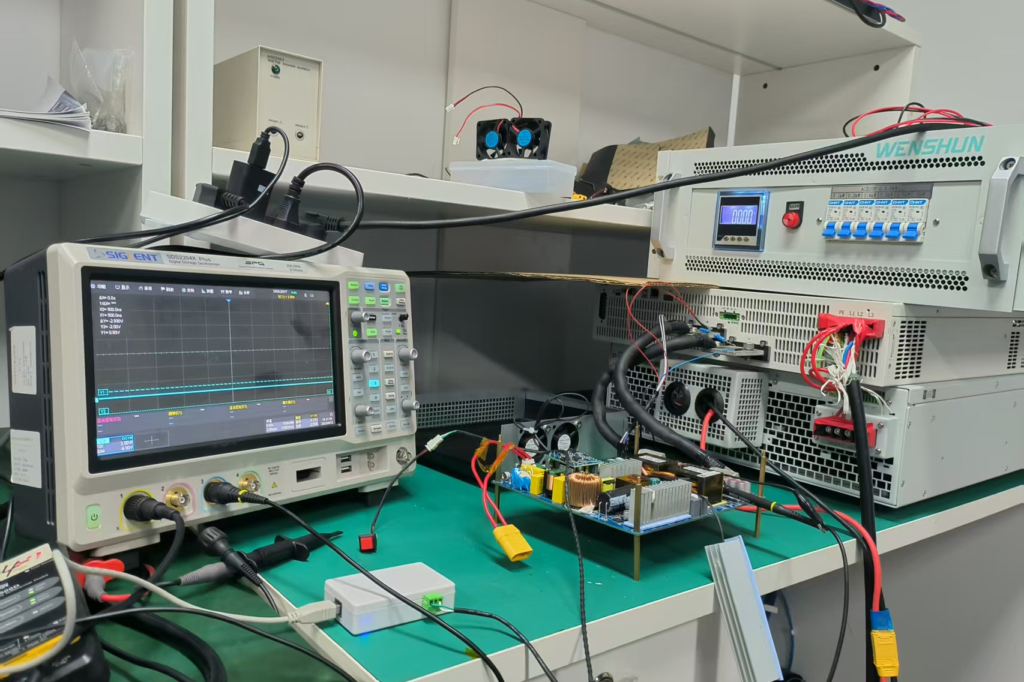

Witroy operates a 9,000 m² smart manufacturing facility in Shenzhen, equipped with over 200 skilled professionals and automated production lines. Our capabilities cover R&D, SMT, assembly, and testing, ensuring efficient and high-quality production. Core equipment includes TRUMPF laser welders, Yamaha SMT lines, high-speed solar stringers, and dual 85 test cabinets. Our in-house lab features AAA solar simulators, IP67 test chambers, and Arbin battery test systems for extreme environment validation.

We take a precision-driven approach to every project, delivering optimized performance and cost-effective results. Our product portfolio includes solar inverters, micro-inverters, portable power stations, and a full range of accessories, with an annual production capacity exceeding 500,000 units.

Portable Power Station Manufacturer

Witroy operates a 9,000 m² smart manufacturing base in Shenzhen, equipped with over 200 professionals and fully automated production lines. We specialize in R&D and production of power control boards, inverters, MPPTs, and integrated energy storage systems.

Our advanced equipment includes German TRUMPF laser welders, Yamaha SMT lines, high-speed solar stringers (99.8% yield), and dual 85 test cabinets (10-year inverter lifespan testing).

We also run a full-featured lab with an AAA solar simulator, IP67 test chambers, and Arbin battery test systems—ensuring high reliability from design to extreme condition testing.

With an annual capacity of over 500,000 units, we serve global needs in portable power, off-grid solar, and residential energy storage.